In CURVASTUR, we have our OWN AND EXCLUSIVE machinery & manufacture processes for the realization of the boiler and other pressure parts works as they are:

· 3 adjacent workshops fully equipped with bridge cranes in all of them and a combined area of 2.200m2 + 2.200m2 +1.300m2, with separate areas for the manufacture of stainless steel if necessary.

· Automatic WALTHER system with controlled movement with two SAW Submerged Arc welding groups with low thermal input for the fabrication of boiler walls.

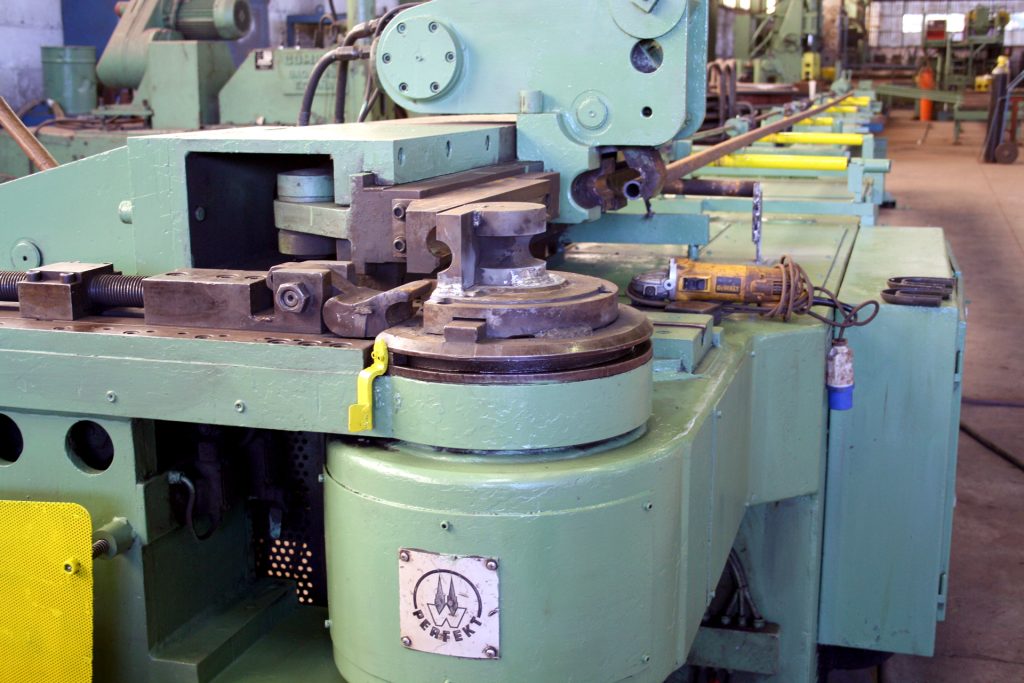

· 6 machines for cold tube bending for R>=1,2*Ø ext (all of them electro-hydraulic machines with rotating arm and fixed radius BOOSTER system to minimize the stretching and loss of thickness of the tube to be bent in its outer zone, up to Øext 168,3mm in any material and thickness).

· Hot bending system for boiler tubes for SMALL RADIOUS R<=1,2*Øext, inclusive less than 1 x Øext; up to tubes Øext 88,9 mm in any material and thickness.

· Hot/cold bending of boiler tubes to make boiler openings· (manholes, blowers, peepholes...) without the need of a straight section between adjacent bends or intermediate welding (up to Øext 114,3 mm in any material and thickness).

· System for concentric diameter reduction of boiler tube ends without welding (“swaging”) (up to Øext 114,3 mm in any material and thickness).(hasta Øext 114,3 mm en cualquier material y espesor).

· 250-ton press brake, 90-ton press and 3-meter roll for sheet metal forming.

· Two latest generation machines for automatic orbital TIG welding of tube/sheet welded joints for heat exchangers with and without consumable supply.

· Torque-controlled electronic expanding machines for expanded tube/sheet joints of heat exchangers.

· Beveling machines, FCAW, TIG, SMAW synergic welding units.

· · Possibility to carry out local thermal works with resistances or in gas furnace with calibrated thermocouples. trabajos térmicos locales con resistencias o en horno de gas con termopares calibrados.

· Cladding of loose tubes, coils or boiler water wall panels with Inconel by robotized workshop process.